Spray Foam: The Ultimate Remedy for Air Sealing and Insulation

Spray foam insulation has become a leading option for reliable air securing and thermal insulation, supplying an unique mix of homes that establish it besides typical approaches. Its capacity to expand and fill up gaps makes it especially efficient in avoiding air leakage, which can dramatically impact power performance. Nonetheless, recognizing the complete range of its advantages, installment processes, and comparisons with other insulation kinds is critical for making informed decisions. As we explore these aspects, the effects for both new constructions and retrofits become progressively considerable. What factors should affect your selection?

What Is Spray Foam?

Spray foam is a functional insulation material that integrates the concepts of air sealing and thermal resistance to boost power effectiveness in structures. Composed mostly of polyurethane or various other comparable substances, spray foam is used as a fluid that broadens upon call with surfaces, creating a strong, continual layer of insulation. This distinct building allows it to load gaps, splits, and gaps that conventional insulation products might ignore, giving an exceptional air seal.

There are 2 major kinds of spray foam: open-cell and closed-cell. Open-cell spray foam is lighter and much more versatile, providing superb noise absorption and a reduced R-value per inch - Spray Foam. In contrast, closed-cell spray foam is denser, providing a higher R-value, moisture resistance, and included structural integrity to developing elements

The application procedure normally includes specific equipment, ensuring a seamless application that complies with different substrates, consisting of wood, metal, and concrete. This adaptability makes spray foam ideal for both brand-new building and constructions and retrofitting existing frameworks. Its capacity to create a closed obstacle considerably adds to decreasing energy intake and enhancing interior air top quality, therefore making it a preferred option among homeowners and builders alike.

Benefits of Spray Foam Insulation

Among the most considerable benefits of spray foam insulation is its remarkable capacity to develop a continual air obstacle, which properly minimizes energy loss. Unlike conventional insulation products, spray foam expands to fill fractures and voids, making sure that air leakage is drastically reduced. This particular not only enhances energy performance but likewise causes reduce energy costs with time.

Furthermore, spray foam insulation gives exceptional thermal resistance, contributing to a more secure interior environment. Its high R-value per inch allows for reliable insulation in confined rooms, making it perfect for attics, wall surfaces, and crawl rooms. The moisture-resistant buildings of spray foam assistance protect against mold and mold growth, promoting healthier living conditions.

One more critical benefit of spray foam insulation is its sound-dampening high qualities (Spray Foam). It effectively minimizes noise transmission in between areas, producing a quieter and a lot more comfy home setting. The sturdiness of spray foam additionally stands out, as it does not sag or settle in time, maintaining its efficiency throughout its life expectancy

Exactly How Spray Foam Works

Recognizing exactly how spray foam insulation functions is essential for valuing its effectiveness in air securing and thermal resistance. Spray foam insulation is composed of 2 main elements: isocyanate and polyol material. When these elements are blended, they undertake a chemical reaction that causes the material to broaden rapidly, producing a dense foam that fills voids, tooth cavities, other and fractures.

As the foam broadens, it sticks to surface areas, creating an impermeable seal that dramatically lowers air infiltration. This particular makes spray foam insulation highly reliable at stopping drafts and moisture infiltration, which can lead to power loss and damage visit here over time. Furthermore, the closed-cell version of spray foam offers exceptional thermal resistance because of its rigid framework, effectively minimizing warm transfer.

The distinct residential or commercial properties of spray foam allow it to satisfy irregular surfaces, guaranteeing extensive coverage and a seamless barrier. As a result, spray foam insulation not only boosts energy performance yet additionally adds to enhanced indoor air quality by lowering the buildup of contaminants and irritants. Eventually, understanding the mechanics behind spray foam highlights its role as an exceptional selection for insulation and air sealing in both property and commercial applications.

Installment Refine Introduction

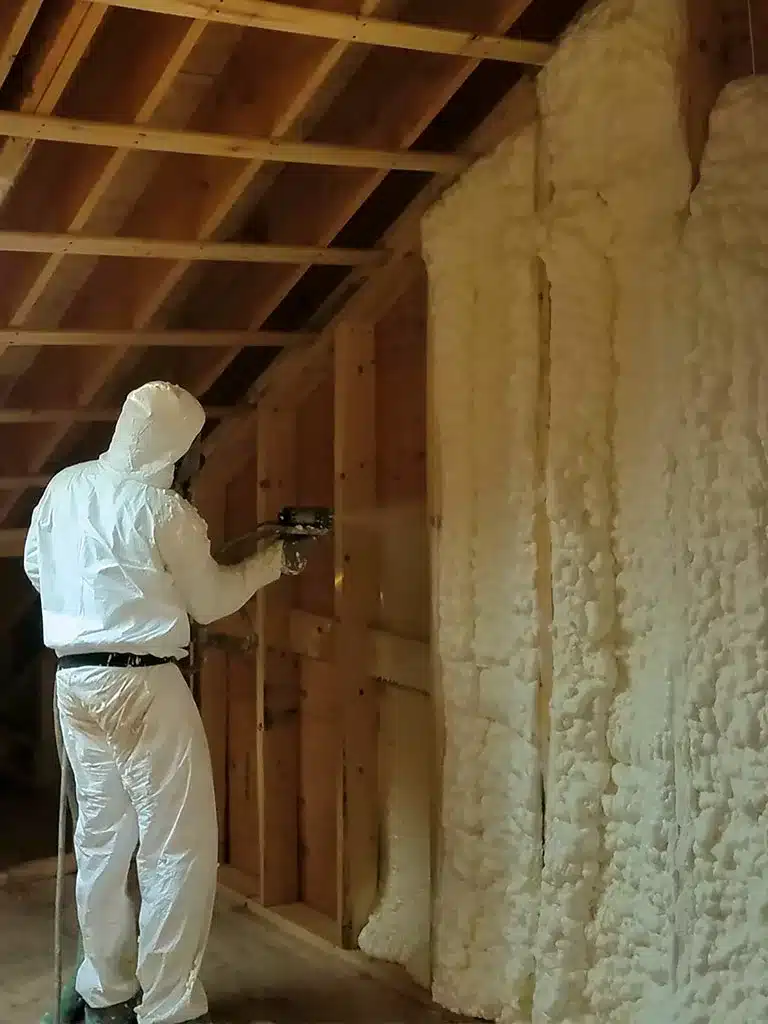

Before installment, the space needs to be appropriately cleaned and prepped, ensuring that surfaces are devoid of dampness, particles, and dirt. Due to the fact that pollutants can endanger attachment and overall performance, this action is essential. When the location is prepared, the application includes mixing the 2 components of the spray foam, which broadens upon contact and fills up spaces effectively.

Trained experts ought to conduct the installment, using specific devices to make sure consistent protection and optimal thickness. Safety and security safety measures, including putting on safety gear and ensuring correct air flow, are necessary during this process. After application, the foam usually cures promptly, developing a solid obstacle that enhances power performance.

Contrasting Spray Foam to Conventional Insulation

When reviewing insulation options, spray foam insulation stands out in contrast to typical materials such as fiberglass and cellulose. Unlike fiberglass and cellulose, which can enable air seepage, spray foam expands upon application, filling gaps and voids to produce a closed seal.

Furthermore, spray foam supplies a higher R-value per inch than standard insulation types, using even more reliable thermal resistance in a thinner profile. This particular is particularly helpful precede with minimal dental caries depth. In addition, spray foam is resistant to wetness and mold development, which can be a considerable worry about cellulose and fiberglass, specifically in damp environments.

Nevertheless, spray foam insulation normally lugs a greater ahead of time expense than its typical equivalents. Homeowners should evaluate this first investment against long-lasting power financial savings and performance benefits. Eventually, while both insulation kinds offer their objective, spray foam emerges as a much more sophisticated remedy for modern-day insulation needs, especially in terms of air securing and thermal effectiveness.

Final Thought

In summary, spray foam insulation represents an extremely effective service for achieving optimal air sealing and thermal resistance. Its unique homes, consisting of wetness resistance and sound dampening, make it suitable for various applications in both brand-new building and constructions and retrofitting jobs (Spray Foam). The preliminary expenses might be greater compared to traditional insulation products, the long-lasting advantages, such as substantial energy savings and boosted indoor air quality, warrant the investment and underscore its worth in modern structure methods.

Spray foam insulation has actually emerged as a leading solution for reliable air sealing and thermal insulation, supplying a special combination of properties that establish it apart from conventional approaches.Spray foam is a versatile insulation product that integrates the concepts of air sealing and thermal resistance to boost energy effectiveness in buildings.When examining insulation options, spray foam insulation stands out in contrast to traditional materials such as fiberglass and cellulose. Inevitably, while both insulation types offer their purpose, spray foam arises as a more sophisticated remedy for contemporary insulation demands, particularly in terms of air securing and thermal performance.

In recap, spray foam insulation represents a very efficient remedy for achieving ideal air securing and thermal resistance.